Low Carbon Steel Straight Type Horizontal Wire Drawing Machine

Description

Basic Info

| After-sales Service | Commission Service, Technical Support |

| Warranty | 1 Year |

| Type | LZ Straight-Line Metal Drawing Machine |

| Usage | Wire |

| Metal Material | Steel |

| Outlet Diameter | 1.2 |

| Max.Inlet Wire Dia. | 6.5mm |

| Block Dia. | 560mm |

| Max. Number of Block | 12 |

| Certification | ISO |

| Condition | New |

| Transport Package | Plastic Film |

| Trademark | Jiake |

| Origin | Made in China |

| HS Code | 846330000 |

| Production Capacity | Max. 16tons/24hours. |

Product Description

Low carbon steel straight type horizontal wire drawing machine

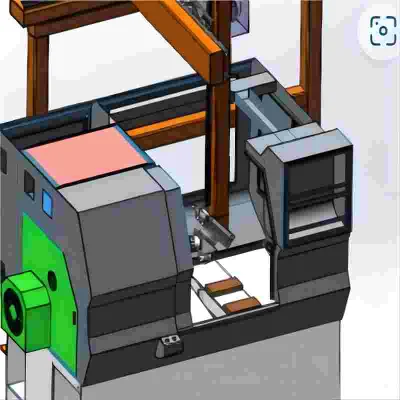

1.Straight wire drawing machine LZ-560A:

The fully automatic wire drawing machine used drawing drum is equipped with Inverter to adjust speed saving 30% electricity. Straight wire drawing machine with hardened reducer, little noise, fast speed, less friction, longer service life. Water cooling technology is to extend machine life efficiently. The finished product is used to produce standard parts (welding rod, wire nail, screw, etc.).

| Straight line nail wire gi wire drawing machine

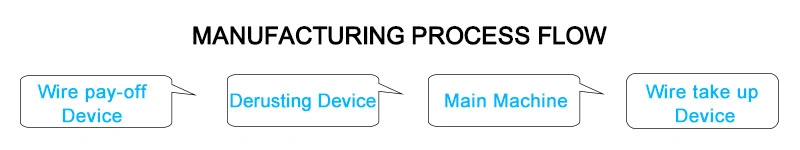

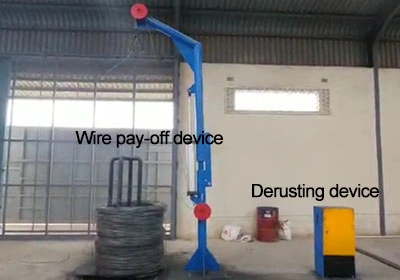

The straight wire drawing machine is a high-speed wire drawing machine. Its main features are that the drum adopts narrow slot type water cooling, which has a good cooling effect.It adopts the first-class strong narrow V-belt and the first-class plane double enveloping worm gear pair for high transmission efficiency and low noise.The fully enclosed protection system has good safety; the air tension tuning is adopted to ensure stable drawing. 1. The work process of the wire drawing machine

2. The Parameters of the Wire Drawing Machine

3. The Feature of the Wire Drawing Machine 1. INOVANCE Inverter adjustable motor and gearbox for adjusting speed, saving 30% electricity;2. Block body is made of thickness high tensile strength steel plate and square tube, shock-resistance.3. Drawing path is painted with the surface of Tungsten carbide, a long lifetime.4. Water cooling system to decrease the working temperature, working smoothly, and service life extended.5. Safety operation with Centralized control panel.6. The main motor is copper leads inside and the motor is at least 18.5KW for enough power supply.7. Hardened reducer, little noise, fast speed.8. Safety operation with steel covers and doors and obvious signs above the drawing blocks.

4. Function of Wire Drawing Machine There are many suitable drawing materials for straight wire drawing machine, including welding rod; welding wire (gas shielded wire, submerged arc wire, flux-cored wire, etc.); steel wire (high, medium, and low carbon steel wire, stainless steel wire, tire steel wire, hose steel wire, spring steel wire, steel cord, etc.); electric wire (aluminum clad steel wire, copper wire, aluminum wire, etc.); alloy wire, etc. 5. Technical Service We provide professional technical support, including technical consultation, machine design, plant layout design, and one-stop solutions.Before-sales Service: Professional technicians solve your problems.After-sales Service: We offer Installation video, Manual and Online service. We can send engineers to train workers in the Client's factory.Spart part Service: Provide lifetime accessories service. 6. Our experience NOW Get a Free Quote from Heibei JIAKE Machinery. | |||||||||||||||||||||||||||||||||||||||||||||||||||

2.Double-block Electric Furnace (Aneal wire)

Electric furnace is used to anneal the wire. So, the wire is not easy to break and can be redrawn into smaller diameter. Each furnace is equipped with three 8 annealing blocks for cycling use. This machine adopts the two-section intelligent separate temperature control, silicon controlled, the precision is very high.

Double-block Electric furnace, can load two annealing blocks each time, high capacity.

| Model | Double-block Electric furnace | Control system | PID Touch screen control |

| Heating method | Electricity | Annealing block | Stainless-steel block |

| Load capacity | Max.15tons | Working temperature | Maximum 1000° |

| Loading size | 1000×2300mm | Voltage | Customized as your request |

| Furnace inner size | 1350×2600×2500mm | Rated Power | 220KW |

| Overall dimension | 2200×3400×3000mm | Weight | 5500KGS |

3. High speed wet drawing machine B17et drawing machine B1

| Power Control | Double Inverter Control |

| Max. Die No. | 17 |

| Inlet Wire Dia. | Max. 2mm |

| Finished Wire Dia. | 0.30 - 0.85mm |

| Max. Line Speed | Max. 1500m/min |

| Slip Ratio | 15% |

| Fixed Speed Capstan Slip Ratio | 10% |

| Drawing Capstan | Carbon Fiber |

| Drawing Power | 22KW |

| Take-up Power | 5.5KW |

| Fixed Speed Capstan Dia. | 200mm |

| Take-up Reel Size | 350mm ,300mm, 400mm or following customers' requirement. |

| Take-up Type | Shaft Type |

| Winding Displacement | 110KW Synchronous Motor+Flat Belt |

| Transmission Type | Synchronous Transmission |

| Take-up Control | PID Displacement Detection, Automatic Control |

| Detecting Device | Weight Balance by Swing Arm |

| Tension Adjusting Type | Weight Balance Type |

| Drawing Capstan Lubrication Type | Fully immersed |

| Brake | Electromagnetic Brake |

| Bearing Lubrication | Oil free |

| Working Voltage | As your request. |

| Size | 2680mm*1200mm*2100mm |

| Weight | 2500KG |

4. Loading photos:

Till now, our mesh welding machine was sold to more than 120 countries and regions including: Russia, Canada, U.S.A., Mexico, Romania, Bulgaria, Greece, Turkey, Algeria, South Africa, Tunisia, Ethiopia, Uganda, UAE, Iran, KZ, India, Thailand, Malaysia, Indonesia, Argentina, Brazil, Guatemala, Peru.And till now, our anticlimb fence welding machine occupied 70% India; our chicken cage welding machine occupied 70% Indonesia;our 25-80 chain link fence machine occupied 70% Thailand.Our wire mesh machine occupied 70% Uganda market.5. FAQ to Hebei Jiake Welding Equipment Co.,LTD

Q1: Where is your factory located?

A: Our factory is located in Anping county, Hebei Province of China. The nearest airport is Beijing airport or Shijiazhuang airport. We can pick you up from Shijiazhuang city.Q2: How many years are your company engaged in the wire mesh machines?

A: More than 25 years. We have our own technology develop department and testing deparment.

Q3: Can your company send your engineers to my country for machine installation, worker training?

A: Yes, our engineers went to more than 100 countries before. They are very experienced.Q4: What's the guarantee time for your machines?

A: Our guarantee time is 2 years since the machine was installed in your factory.Q5: Can you export and supply the customs clearance documents we need?

A: We have much experience for exporting. And we can supply the CE certificate, Form E, passport, SGS report etc, your customs clearance will be no problem.

6. Our factory - Hebei Jiake Welding Equipment Co.,LTD

Hebei Jiake Welding Equipment, founded in 2000, is located at the junction of Bejing, Tianjin and Shijiazhuang - Anping county, which is famous as "Hometown of wire mesh" in China. We are a professional manufacturer of wire mesh machinery. Our company has been developing smoothly and quickly and now we have more than 100 employees. We have our own wire mesh machinery and several pilot plants with strong technical force and advanced production and checkout equipment.Our main products: 3D panel production line, steel bar mesh welding machine, CNC fence mesh welding equipment, EPS panel production line, 3D panel wire mesh machine (bevel inserting combination joint machine), reinforcing construction mesh (heat separate mesh) welding machine, welding equipment of mine sieve mesh, breed aquatics mesh welding machine, floor warming mesh welding machine, steel grating welding equipment, hexagonal mesh weaving machine, expanded metal machine, razor wire machine, Diamond mesh machine, pneumatic spot welding machine and straightening & cutting machine.

7.Our customers - Hebei Jiake Welding Equipment Co.,LTD

We stick to the business principle of "Favorable comments from high quality product and service", and thus we supply a whole-process service from product designing, developing, producing, installing and after-sales service for the clients with first-class techniques top-grade products. Our company has been awarded the title of "Credible and Reliable Product & Service Supplier" by numerous users. We also keep developing on basis of superexcellent management level and advanced development consciousness so as to bring our machinery to both domestic and overseas markets.We sincerely look forward to your cooperation in future and warmly welcome your arrival to build our common beautiful future.

8.Contact Us:

Mr. Polar Xiao (Sales Manager) .................................................................... 1. China DAPU Group (subsidiary: Dapu & Jiake & Rongkuai).2. China No.1 manufacturer of steel wire mesh machinery since 1999.

Our Contact